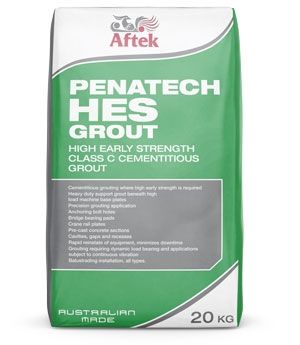

AFTEK PENATECH HES GROUT

Description

<p>Aftek Penatech GP Grout is a general purpose high strength, precision Class C grout. Its non shrink dual expansion compensates for shrinkage in both the plastic and hardened state. Penatech GP complies with US Corp of Engineers Specification of non-shrink grout, CRDC 621-82A and ATSM C1107-91 (Type C). It is ideal for machine base plates where critical grouting application is required. </p><p><b>Features:</b></p> <li>High early and ultimate strength</li><li> Exceptional flow characteristics, good flow retention</li><li> High ultimate (28 day) strength</li><li> Shrinkage compensated in both plastic and hardened state</li><li> Non-metallic wires content eliminates staining</li><li> Complies with ASTM C1107-91 and CRDC-621-82</li><li> Good impact and thermal resistance</li><li> Can be dry packed</li> </p><p><b>Ideal for:</b></p> <li>Applications subject to dynamic loads and where continuous vibration is present</li><li>Bridge bearing pads, crane rail sole plates</li><li>Pre-cast concrete sections and panels</li><li>Anchor bolt fillings</li><li>Filling in core holes, cavities, gaps and base infills</li><li>High performance structural grouting</li> </p><h2>APPLICATION</h2> <p><b>Surface Preparation:</b></p><p> The substrate to be grouted must be clean, sound and free from dust, oil, grease, curing compounds or any foreign matter that will affect the grout adhesion bond. Bolt holes and anchor points must be clean and free of water. All prepared areas must be saturated with water for a minimum of 4 hours prior to grouting. Prior to grouting, ensure all excess water is removed and all holes must be free from water and no puddles of water are present. If grouting under base plates, it is imperative that bleed holes or venting holes are provided (this will eliminate pressure build up in a confined area). </p><p>For grouting requiring thicknesses greater than 200mm, special procedures are necessary. Contact the manufacturer or refer to the Technical Data Sheet for further information. </p> <p><b>Mixing:</b></p><p> Penatech GP Grout is ready to use, simply requiring the addition of water. Penatech GP Grout must be mixed with a mechanical mixer with a high shear mixer or a suitable drum mixer that creates a forced action mixing. </p> <p><b>Placement:</b></p><p> Penatech GP Grout can be placed in two different ways: For gravity flow using a header box: Mix the grout to a flowable consistency and pour grout from one side to avoid air entrapment. Ensure a grout head box is used and the grout head is maintained at all times. This will ensure continuous flow of grout without the possibility of air entrapment.</p><p>For large volume pumping: Mix the grout using a forced action mixer. A positive displacement pump is the recommended pump for large placement application. For large grout pours ensure the grout is pumped from the bottom upwards as this will minimize any air entrapment and ensure complete void filling. For base plates pump from one side ensuring an air bleeder hole is available in the formwork or base plate to ensure any build- up of pressure is released from the bleeder hole.</p><p>On completion of grout application, it should be cured in accordance to good practice with plastic sheet, hessian or curing compounds such as Curecon. </p><p><b>Clean Up:</b> </p><p> Wash all tools and equipment with fresh, clean water immediately after use. Hardened material can only be removed mechanically. </p><b>Storage:</b><p> Shelf life of 9 months if stored in the original sealed packaging in a dry, cool environment. </p><b>Yield:</b><p> One bag yields approximately 10.2 litres of trowellable grout or 11 litres of flowable grout.